Categories

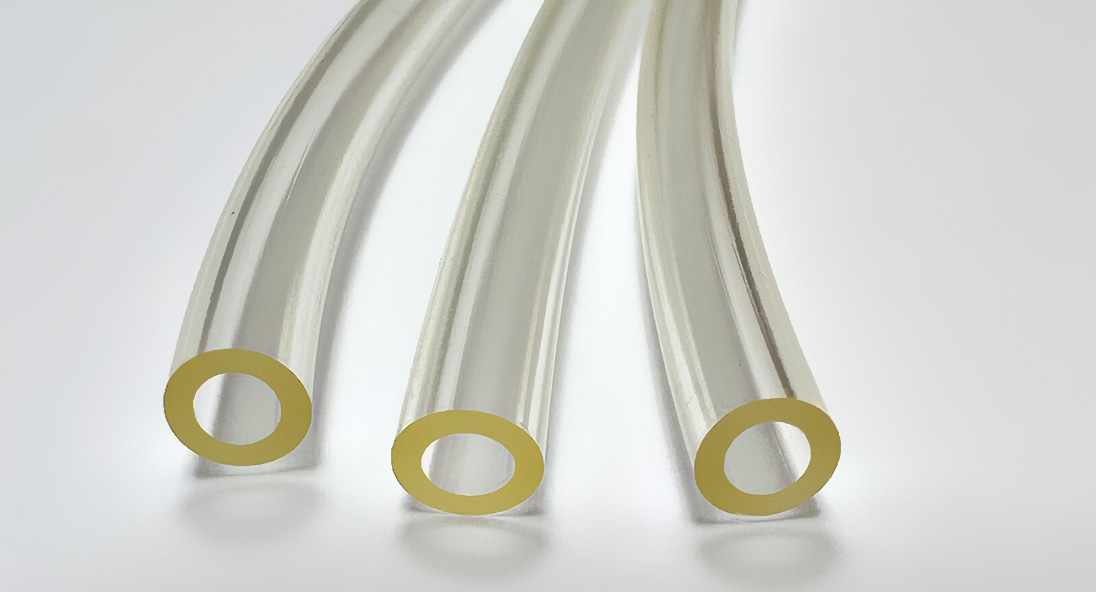

It has many varieties, usually produced using PU raw materials, with stable quality, high pressure resistance, weather resistance, wear resistance, resistance to twists and turns, smooth and flexible pipe body, bright color, high elasticity, resistance to winding, and small bending radius.

Color

Transparent,Natural Matte,various surface textures (fine fabric, fine matte, etc.) Color matching (with minimum order quantity requirements for colors)

Product Name:TPU Tube

performance comparison of plastics for blow molding pneumatic pipe. The Pneumatic tube formed by blow molding is in a thermo elastic state, and its density is smaller than that after cooling and setting, resulting in shrinkage.

For Pneumatic tube with less strict size, the molding shrinkage has little effect. For Pneumatic tube of specified size, such as some hoses used for precision machines, large shrinkage has a considerable impact.

The larger the volume of blow molding, the more significant the impact. The advantages of extruding blown plastic forming Pneumatic tube are: less investment in production equipment, simple equipment structure, easy mold manufacturing, high molding of pneumatic tube during production, uniform temperature control, and various specifications of Pneumatic tube can be formed.

The disadvantage is that the wall thickness uniformity of Pneumatic tube is poor. The advantages of injection blown Pneumatic tube are that the molded plastic Pneumatic tube has good product quality, accurate overall dimensions, no seam, uniform wall thickness, can be produced by multi mold molding, high degree of automation, and is suitable for mass and efficient production of small specifications.

The disadvantage is that the investment in equipment and forming molds is relatively large, and technical workers are required for operation and production.

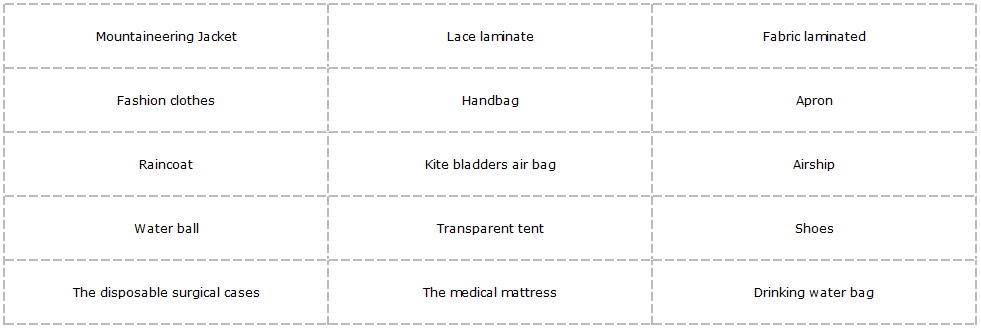

Air mattress tube

Calf cuff inflatable tube

Lumbar support

Breast pump catheter

Medical-grade infusion tube

Color

Transparent,Natural Matte,various surface textures (fine fabric, fine matte, etc.) Color matching (with minimum order quantity requirements for colors)

Specifications

Thickness:0.05-0.5mm(Accept customization)

Width:10-1568mm(Accept customization)

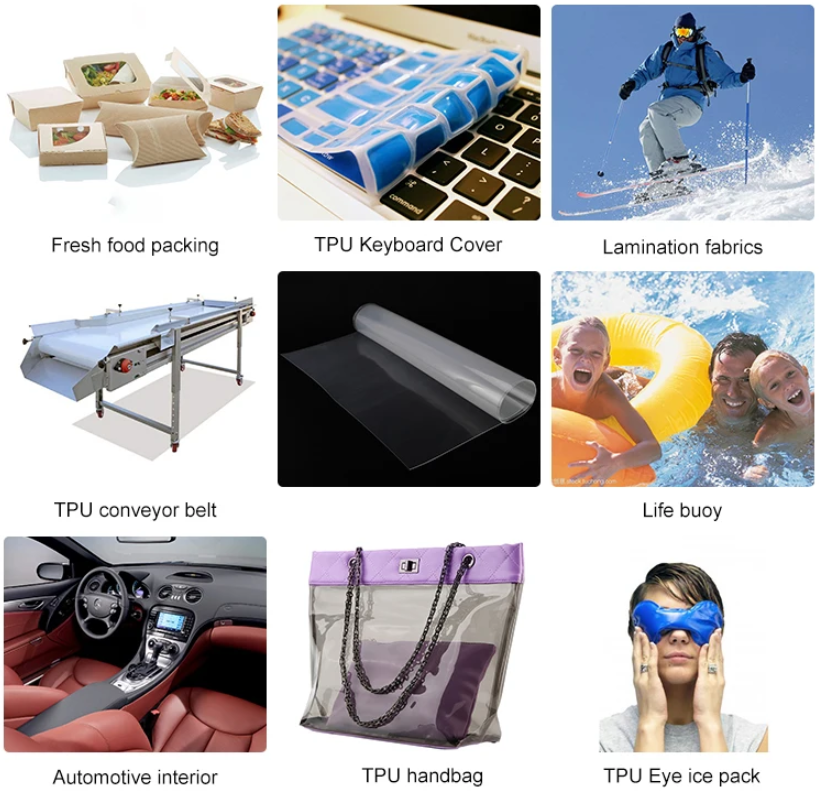

● TPU Film 、TPU Hotmelt Adhesive Film、TPU Lamination Fabric、TPU Bulletproof Film、TPU Blowing Film

● TPU Tapes/Mobilon Tapes 、TPU Synthetic Leather 、 TPU Tubing 、TPU Tapes、 Car Ppf Film

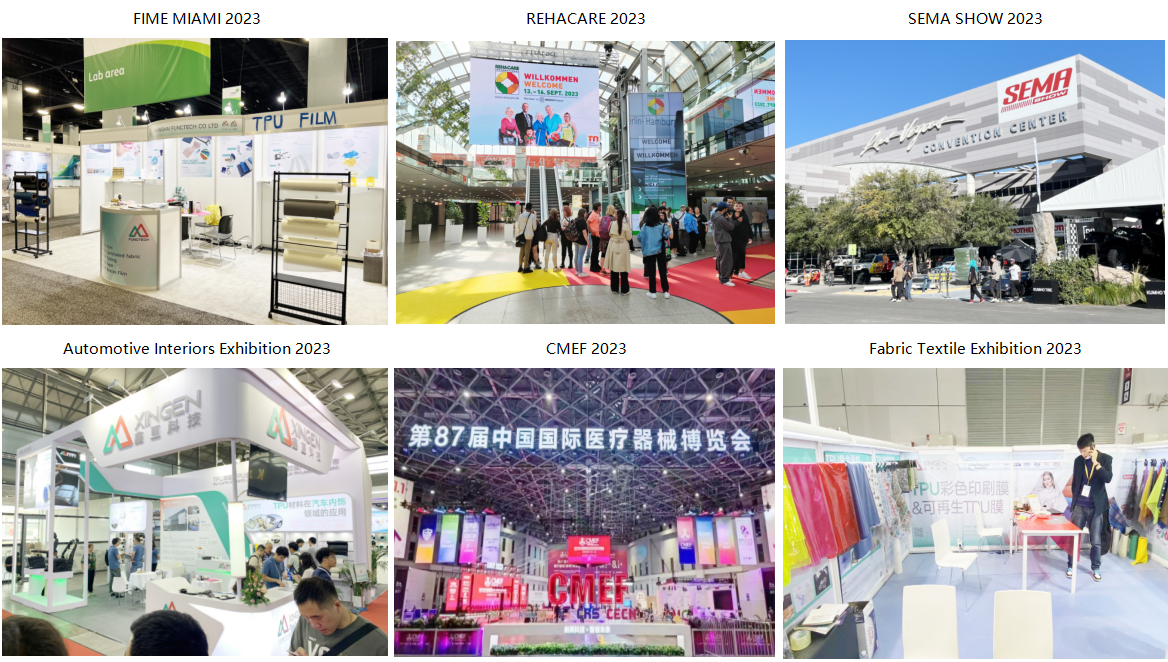

XIN GEN specializes in the R&D and production of high-end TPU products, the products have been widely sold in the international market, it’s application covers clothing textile, outdoor products, luggage and shoe materials, packaging industry, electronics industry. advertising industry, automobile industry, medical industry and other industrial applications.

Main Certificate:

SO9001:2015, OHSAS18001:2007, OEKO-TEX, SGS, ROHS, REACH, EU 10_ 2011 and other third-party certification agencies

certification.The factory has a research and development center and a product laboratory to ensure the quality of products. All employees of XIN GEN are united and committed to the company's mission,vision and values, and contribute to the environmentally friendly green life of customers, society and all mankind.

Call Us:+86-15221216273

Email: info-sz@xgtpu.com