What material is TPU film?

12-23, 2023

|

12-23, 2023

|

View:

View:

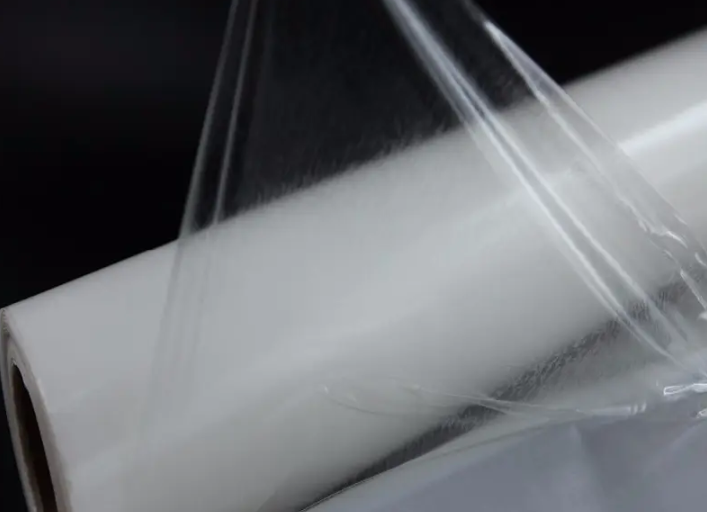

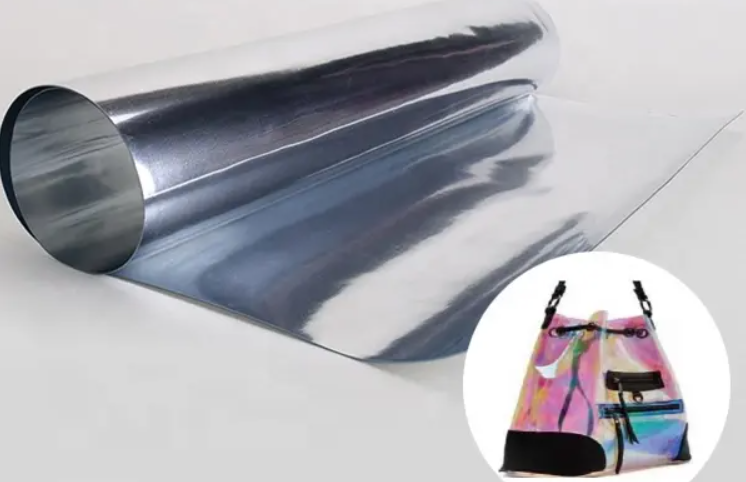

TPU film is a film material made of thermoplastic polyurethane. It has good elasticity, wear resistance, tear resistance and cold resistance, and is widely used in various fields. This article will introduce in detail the chemical composition, physical properties, preparation process, application fields, advantages and disadvantages of TPU films.

1. Chemical composition

TPU film is made of thermoplastic polyurethane raw material. Polyurethane is a polymer produced by reacting polyols with polyisocyanates or polyesters. When preparing TPU films, by controlling the ratio of raw materials and reaction conditions, the composition and performance of TPU can be adjusted to give it different characteristics.

2. Physical properties

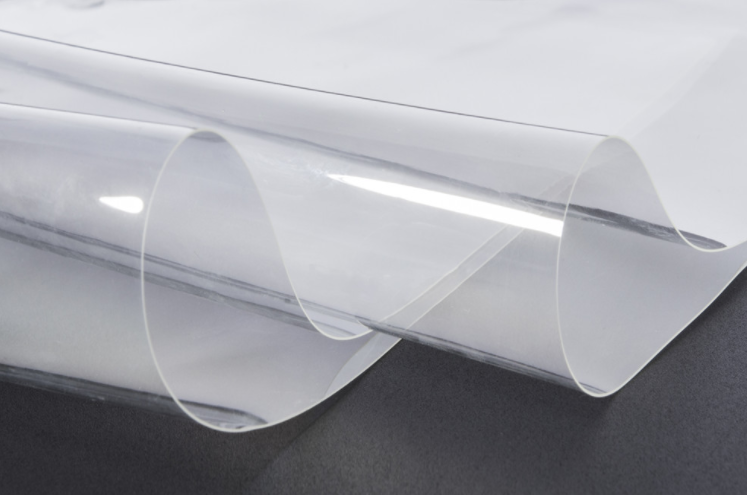

Elasticity: TPU film has excellent elasticity and can return to its original shape under greater stretching. This makes TPU films excellent in applications that require a high degree of flexibility and resilience.

Wear resistance: TPU film has excellent wear resistance and can withstand friction and surface wear without being easily damaged, so it is suitable for occasions requiring long-term use.

Tear resistance: TPU film has high strength and tear resistance, and can maintain good integrity even under the action of tearing force.

Cold resistance: TPU film can still maintain its elasticity and flexibility in low temperature environments and is not easy to become brittle, so it is suitable for applications in low temperature environments.

3. Preparation process

TPU films are usually prepared by extrusion or calendering. The extrusion method is to extrude pre-prepared TPU particles into a film shape through a heated and pressurized extrusion mechanism, and then solidify by cooling to obtain a film. The calendering method is to place TPU particles between two metal rollers, and press the particles into a film shape under the action of high temperature and high pressure.

4. Application areas

TPU films are widely used in various fields. The following are several main application fields:

Clothing and footwear: TPU films can be used to make waterproof, breathable and abrasion-resistant clothing and footwear materials, providing a comfortable and durable experience.

Packaging materials: TPU film can be used in food packaging, pharmaceutical packaging, electronic product packaging and other fields, and has good sealing and protective properties.

Medical devices: TPU film can be used in the production of medical devices such as catheters, infusion bags, surgical gowns, etc. It has excellent biocompatibility and softness and is harmless to the human body.

Automotive interiors: TPU films can be used as covering materials for car seats, dashboards and other interior parts. They have the properties of waterproof, anti-pollution and wear-resistant.

Electronic products: TPU films can be used in mobile phone cases, electronic device screen protectors and other fields to provide protection and comfortable touch.

5. Advantages and Disadvantages

TPU film has the following advantages:

Good elasticity and flexibility, suitable for a variety of application scenarios.

Excellent wear and tear resistance and long service life.

It has good cold resistance and is suitable for applications in low temperature environments.

The preparation process is relatively simple and can be produced at low cost.

However, TPU film also has some disadvantages:

It has poor tolerance to high temperature environments and is prone to softening or deformation.

Sensitive to certain chemicals, corrosion or discoloration may occur.

TPU film is a film material made of thermoplastic polyurethane with excellent elasticity, wear resistance, tear resistance and cold resistance. It is widely used in clothing, footwear, packaging, medical equipment and other fields. Although TPU film has some shortcomings, its superior physical properties and preparation process make it an ideal choice for many applications.