The difference between PTFE film and TPU film

12-23, 2023

|

12-23, 2023

|

View:

View:

PTFE film and TPU film are two materials with different chemical compositions, physical properties, application ranges and process characteristics. The following will introduce and compare PTFE membrane and TPU membrane in detail to better understand the differences between them.

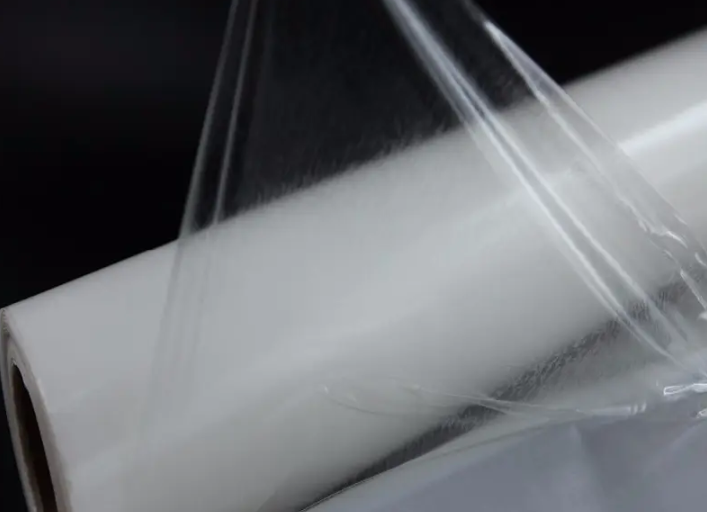

PTFE membrane overview

PTFE (polytetrafluoroethylene) is a polymer material with strong acid resistance, alkali resistance, corrosion resistance, excellent low friction coefficient, low surface energy and extremely high temperature resistance. PTFE membrane is a single or multi-layer film material made of polymerized tetrafluoroethylene. PTFE membrane has excellent chemical stability and is widely used in chemical industry, electronics, machinery, aviation and other fields.

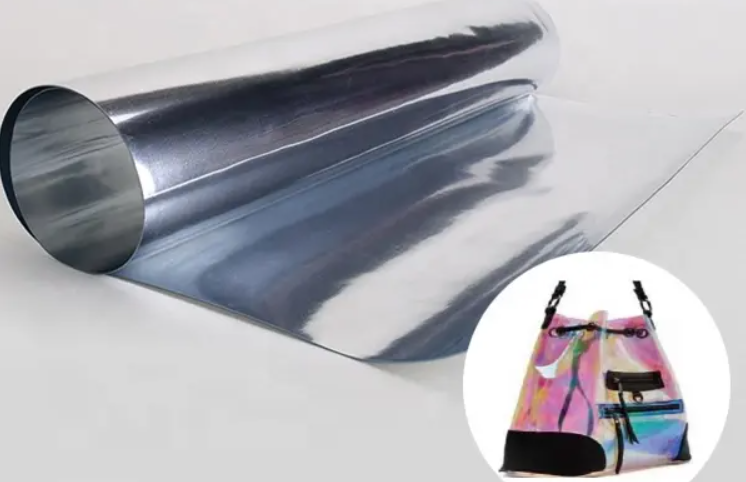

TPU film overview

TPU (thermoplastic polyurethane) is a new type of polymer material with good elasticity, wear resistance, tear resistance, cold resistance, and high strength. TPU film is a film material made of TPU raw materials. TPU film has excellent wear resistance and softness and is widely used in clothing, footwear, packaging, medical equipment and other fields.

The difference between PTFE membrane and TPU membrane

chemical components

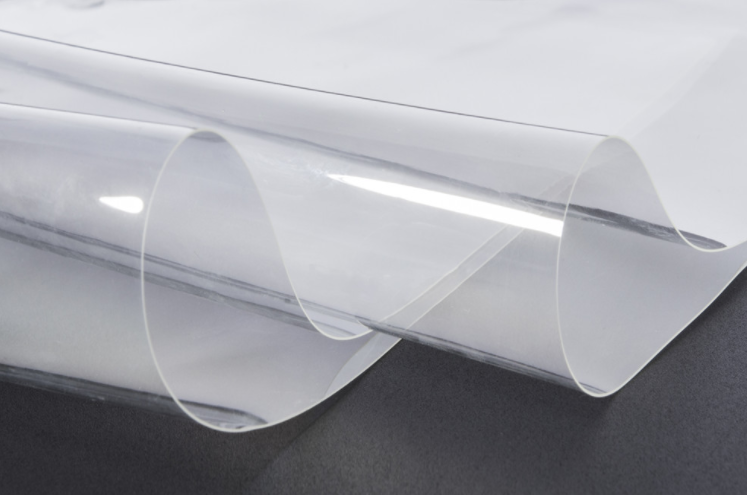

PTFE membrane is made of polymerized tetrafluoroethylene, while TPU membrane is made of thermoplastic polyurethane raw material. The PTFE membrane does not contain other materials in its chemical composition, while the TPU membrane can be adjusted by adding other chemical components.

physical properties

PTFE membrane has extremely low surface energy and friction coefficient, and is acid and alkali resistant, high temperature resistant, and corrosion resistant. The TPU film has good elasticity, softness and wear resistance. There are big differences in the physical properties of the two, and their applicable fields are also different.

Application scope

PTFE membrane is mainly used in chemical industry, electronics, machinery, aviation and other fields; TPU film is mainly used in clothing, footwear, packaging, medical equipment and other fields. Both have their own application ranges and are applicable to different scenarios.

Process characteristics

The production process of PTFE membrane is complex and requires chemical synthesis. The film can also be made by cutting or calendering. The production process of TPU film is relatively simple and is generally prepared by extrusion or calendering.

cost

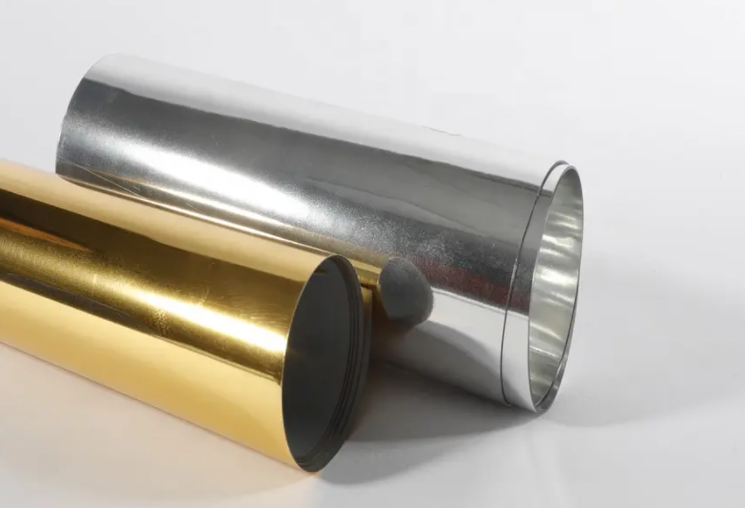

PTFE membrane is a high-end material with complex production process, high price and high cost. The TPU film is relatively more affordable and the cost is relatively low.

There are obvious differences between PTFE membrane and TPU membrane in terms of chemical composition, physical properties, application scope, process characteristics and cost. PTFE membrane has excellent corrosion resistance, low friction coefficient and high temperature stability, and is widely used in chemical industry, electronics, machinery, aviation and other fields. TPU film has good elasticity, softness and wear resistance, and is also widely used in clothing, footwear, packaging, medical equipment and other fields. Choosing the right material depends on the specific application requirements.