TPU film service life

12-20, 2023

|

12-20, 2023

|

View:

View:

The service life of TPU film is determined according to different application scenarios and usage conditions. Detailed introduction below:

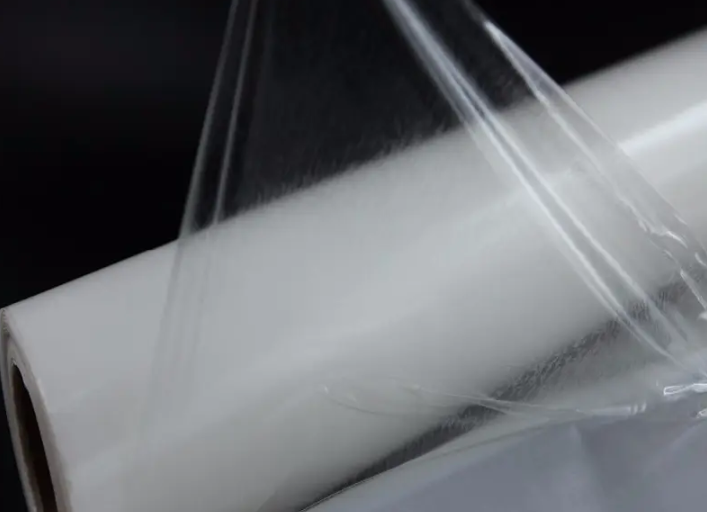

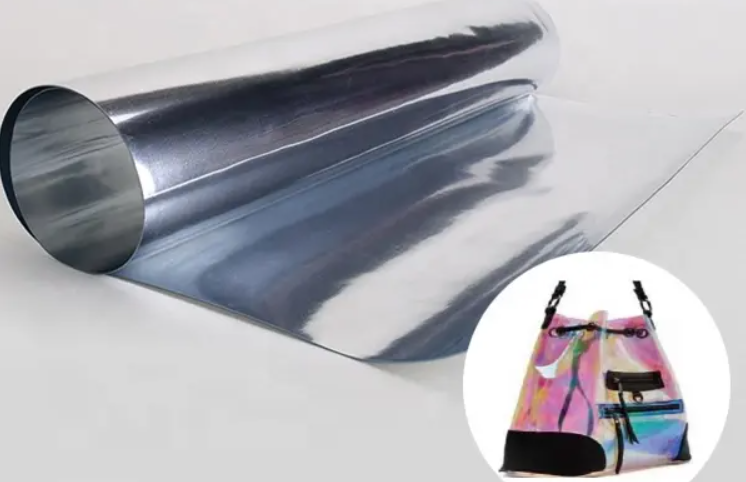

TPU film is a high-performance material with excellent physical and chemical properties and durability, so it is widely used in many fields. It is widely used in medical, electronics, automotive, textile, packaging and other industries, and its uses include waterproofing, dustproof, heat insulation, protection, etc.

The service life of TPU film is affected by many factors, including the following aspects:

Usage environment: The service life of TPU film is related to the environment in which it is located. If used under harsh environmental conditions, such as high temperature, low temperature, ultraviolet radiation, etc., the performance and life of the film may be affected. Therefore, when choosing TPU film, you need to consider the usage environment and choose the appropriate model and specifications.

Stress and load: TPU film will bear certain stress and load during use, such as stretching, bending, pressure, etc. Excessive stress or long-term overload use may cause fatigue and damage to the film, thereby shortening its service life. Therefore, it is necessary to reasonably evaluate stress and load when designing and using TPU films, and take appropriate measures to reduce stress concentration and damage.

Maintenance: The maintenance of TPU film plays an important role in extending its service life. Regular cleaning, keeping dry and proper storage conditions can help ensure the performance and longevity of the film. At the same time, avoiding contact with sharp objects, corrosive substances, etc. is also the key to protecting the film.

Quality and manufacturing process: The quality and manufacturing process of TPU film directly affect its service life. High-quality raw materials and strict manufacturing processes can give the film better performance and durability, thereby extending its service life. When choosing a supplier, you should choose an experienced and reputable one to ensure the quality and reliability of the film.

It should be noted that the service life of TPU films will vary according to different uses and application scenarios. For example, in the medical field, TPU films are often used for packaging and protection of medical products, and their service life may be short, depending on the use cycle of the product. In other areas, such as the automotive and electronics industries, TPU films may be subjected to more severe conditions and therefore require a longer service life.

To sum up, the service life of TPU film is comprehensively affected by multiple factors. When selecting and using TPU films, factors such as the use environment, stress and load, maintenance, quality and manufacturing process need to be considered, and corresponding measures should be taken according to the actual situation to extend its service life. Regularly checking and maintaining the condition of the TPU film is also an important step to ensure its performance and lifespan.