TPU protective film process flow

12-15, 2023

|

12-15, 2023

|

View:

View:

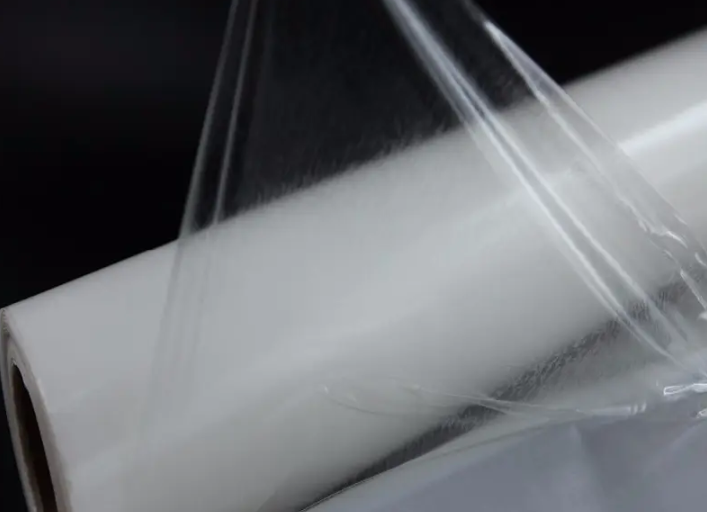

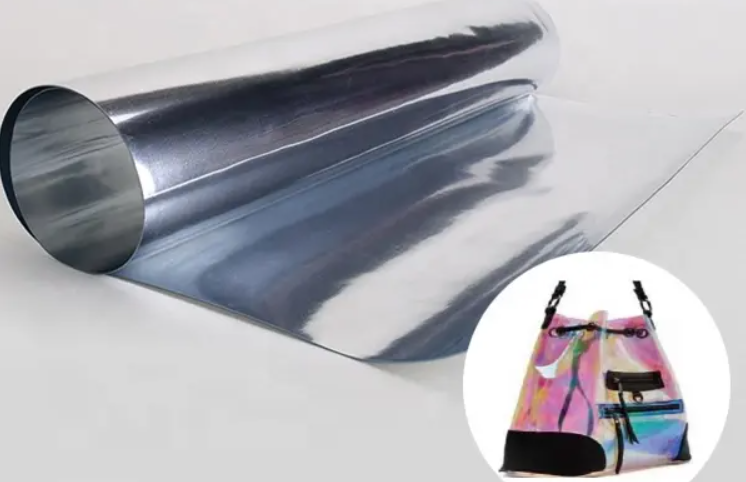

The process flow of making TPU protective film is relatively simple. The following is the general production process:

Raw material preparation

The main raw material of TPU protective film is thermoplastic polyurethane (TPU) particles. Raw materials need to be inspected, screened and proportioned before production to ensure the quality and stability of the raw materials.

Melt preparation

Put the prepared TPU particles into the melt preparation equipment, add appropriate amounts of additives and color masterbatch, and melt the TPU particles into a melt under high temperature and high pressure. During this process, factors such as the temperature, pressure, and mixing speed of the melt need to be controlled to ensure the uniformity and stability of the melt.

coating

Coat the melted TPU melt evenly on the base paper or other substrates. Coating can be carried out by roller coating, blade coating or spraying. During the coating process, parameters such as coating thickness, coating speed, and coating temperature need to be controlled to ensure the uniformity and stability of the coating.

dry

The coated TPU film needs to be dried to change it from a high-humidity state to a dry state. Drying can be carried out by hot air or infrared heating. During the drying process, parameters such as drying temperature, drying time and drying speed need to be controlled to ensure the dryness and physical properties of the film.

Coating treatment (optional)

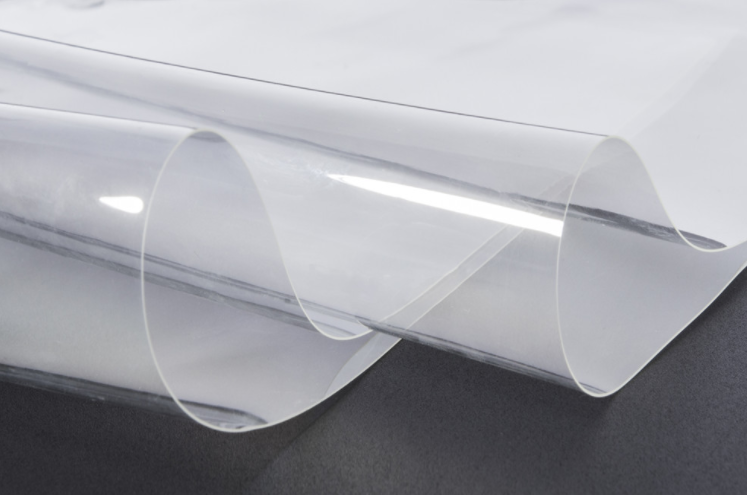

As needed, the TPU protective film can be coated to add anti-scratch, anti-fingerprint, anti-UV and other functions. Coating can be carried out by solution dipping, hot melt coating or vacuum evaporation. During the coating treatment process, parameters such as coating thickness, coating uniformity and coating adhesion need to be controlled to ensure the performance and stability of the coating.

Test packaging

The TPU protective film after drying and coating treatment (if any) needs to be quality tested and packaged. The inspection includes testing of film thickness, width, transparency, tensile strength, heat resistance and other indicators to ensure that the film meets product requirements. Packaging is to roll or cut the film into sheets of different specifications, and then package and label them.

The production process of TPU protective film is relatively simple, mainly including raw material preparation, melt preparation, coating, drying, coating treatment (optional) and testing and packaging. Each step requires control of relevant parameters to ensure the quality and performance of the protective film. Through reasonable process flow and strict quality control, high-quality TPU protective film products can be produced.