tpu material composition

12-09, 2023

|

12-09, 2023

|

View:

View:

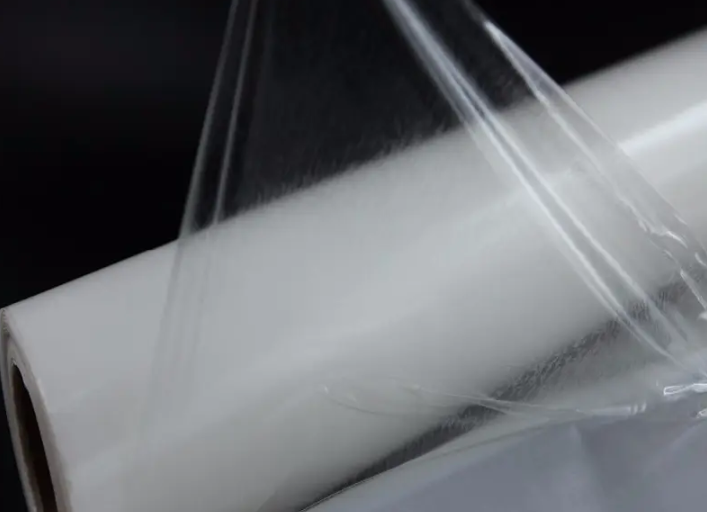

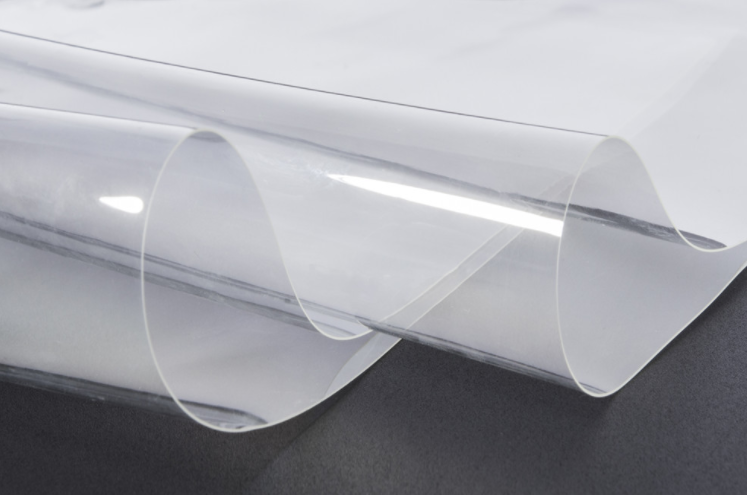

TPU is a polymer material, which is a type of plastic and is widely used in various fields because of its excellent performance. The full English name of TPU is Thermoplastic Polyurethane. This material has the elasticity of rubber and the processing properties of plastic. It is a polymer material between rubber and plastic.

The basic components of TPU include hard segments and soft segments. The hard segment is mainly composed of Diisocyanate, while the soft segment is composed of long-chain polyether or polyester polyol Polyol. These two components are linked through a chemical reaction to form the backbone of TPU. During the synthesis process of TPU, some chain extenders are also added, usually low molecular weight polyols or amine compounds, to adjust the physical and mechanical properties of the material.

TPU is characterized by excellent wear resistance, oil resistance, low temperature resistance, chemical resistance and good mechanical properties, such as high strength, high elongation, high elasticity and impact resistance. These properties make TPU widely used in shoe materials, automotive interior and exterior parts, medical equipment, wires and cables, films and fibers, and other fields.

With different ratios of hard segments and soft segments, TPUs with different hardnesses can be prepared to meet the needs of different applications. The hard segments provide the material's strength and wear resistance, while the soft segments give the material good flexibility and elasticity. By adjusting the ratio of hard segments and soft segments, TPU with different hardnesses from rubbery to hard plastic can be obtained.

In the synthesis process of TPU, isocyanate is one of the key raw materials. There are many types of isocyanates, common ones include MDI, TDI, etc. Different types of isocyanates will affect the performance and application of TPU. For example, MDI-based TPU generally has better wear resistance and chemical resistance, while TDI-based TPU has better cold resistance and elasticity.

Long-chain polyols are also an important component of TPU synthesis and are mainly responsible for providing the material's flexibility. Polyether polyols and polyester polyols are two commonly used long-chain polyols. Polyester TPU has excellent wear resistance, tear resistance and good oil resistance, and is suitable for applications requiring wear resistance and oil resistance; while polyether TPU has better hydrolysis resistance and microbial erosion resistance. resistant and suitable for applications with long-term exposure to moisture.

During the production process of TPU, some additives are also added to improve the processing performance of the material and the performance of the final product, such as stabilizers, antioxidants, UV absorbers, colorants, etc. The use of these additives can make TPU materials perform better in specific applications.

TPU is processed in various ways. Common processing methods include injection molding, extrusion molding, blow molding, hot press molding, etc. These processing methods allow TPU to be made into products of various shapes and sizes to meet the needs of different industries.

In general, TPU is a polymer material with adjustable structure, excellent performance and wide application. It combines the advantages of rubber and plastic and has shown its unique value in many fields. With the development of science and technology, TPU synthesis technology and processing technology are also constantly improving. I believe that there will be more innovative applications of TPU materials in the future.